Why Steel Doors in Historic Brick Walls Need Special Fire Safety Assessment

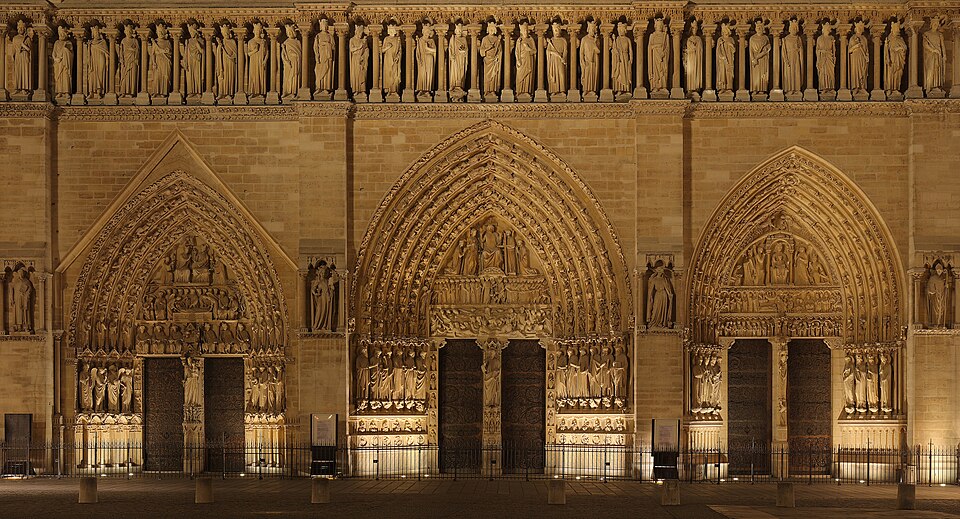

One of the most critical fire safety measures to be implemented in every building is the use of fire-rated doors to safeguard spaces and evacuation routes from the spread of fire and smoke. In numerous instances, steel doors are employed for this purpose, effectively accomplishing the task. However, in historic masonry buildings, a more specific assessment may be more appropriate.

To better understand this aspect of fire protection engineering, an introduction may be helpful, keeping in mind that wooden doors require a different type of assessment.

Fire Resistance Characteristics of Historic Masonry and Brick Walls

Historic masonry and brick walls, central to heritage structures, offer substantial passive fire protection due to their thickness, density, and low combustibility:

- Thermal Mass & Heat Transfer. Solid brick and stone masonry walls—often 240 mm (single layer) up to 500 mm (multi-layer/rubble infill)—deliver significant thermal inertia, retarding heat transfer and protecting unexposed surfaces. Standard furnace testing (ISO 834/EN 1363-1) shows that a 250 mm brick wall can delay a 140°C rise on the protected surface for 60 ore more minutes, while 400 mm stone masonry can resists fire for 120–180 minutes or more.

- Low Combustibility. Materials such as fired clay brick and lime-based mortar are classified Euroclass A1—non-combustible—per EN 13501-1, with typical fusion points above 1000°C and negligible heat release rates. This inherent non-combustibility ensures these materials do not contribute fuel to the fire load.

- Time-Temperature Response and Failure Modes. Unreinforced historic masonry walls can attain integrity and insulation ratings of up to 180 minutes, with figures exceeding 120 minutes for 300 mm solid brick. The maximum deformation recorded prior to failure for robust masonry ranges from 20 to 40 mm. However, local openings such as doors and lintels can increase this deformation by 10 to 30%. In contrast, lightweight stud walls, particularly those with gypsum-sheathing, exhibit significantly higher deformations, reaching up to 100 mm.

- Moisture Effects. Masonry often contains 5–15% pore moisture. Rapid fire exposure may produce up to 25 mm spalled depths, reducing fire resistance by 10–15%.

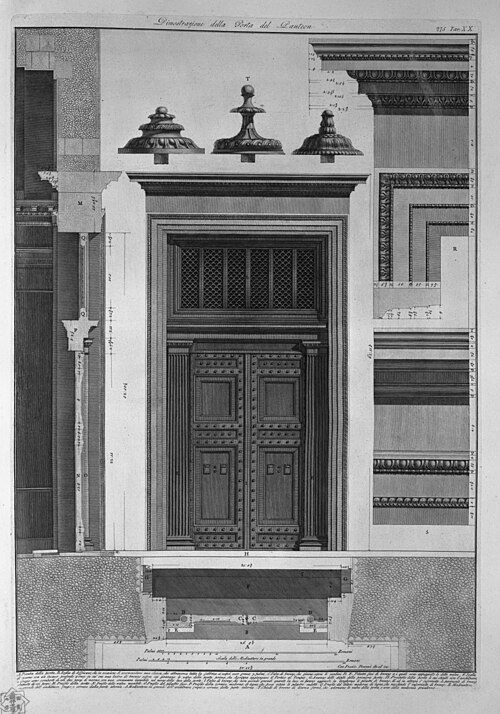

- Impact of Wall Configuration and Modifications. Wall thickness and opening elements critically affect fire performance. For instance, a 400 mm stone wall with steel-framed openings exhibits 30–50% higher local deflection at those sites after 60 min exposure . Internal insulation retrofits must be carefully designed: inappropriate interventions can raise condensation, diminish both energy and fire performance by up to 20%.

Effects of steel frames on wall deformations subjected to fire

Recent experimental research has highlighted that the interaction between fire-rated steel doors and masonry (brick) walls can lead to significant differences in deformation during a fire, with critical implications for heritage contexts (Prieler et al., 2023 “Experimental analysis of the wall deformation of masonry brick and gypsum-sheathed stud walls during standardized fire resistance tests of steel doors“).

When exposed to fire, steel doors expand rapidly due to their high thermal conductivity and low thermal mass compared to surrounding masonry. This differential expansion imposes mechanical loads on the adjacent brickwork, potentially resulting in increased local wall deformation or the formation of gaps at the wall–frame interface.

Prieler documented that, in standardized fire resistance tests, maximum deformations in masonry walls hosting steel doors were measured between 20 and 40 mm—even for robust historic brickwork—while the steel door itself undergoes a different deformation regime. In the case of lightweight stud walls, deformations could reach up to 100 mm, but even in brick walls, the direct interaction at the interface is critical.

This effect is particularly relevant for historic buildings where the original wall fabric and mortar joints may be more vulnerable to stress and thermal gradients. In such contexts:

- Differential Deformation: Steel doors can create stress concentrations on old brickwork due to their rapid thermal expansion.

- Gap Formation: The mismatch between door frame expansion and wall movement can result in gaps that compromise fire compartmentation, allowing passage of hot gases and smoke.

- Heritage Risk: Retrofit interventions that don’t factor in these deformation interactions can inadvertently increase fire risk and jeopardize the heritage value of original materials.

Best Practice Recommendations

- Every steel fire door installed in a heritage brick wall should undergo a site-specific fire safety assessment that incorporates the expected deformation interactions.

- Validate installations via modern fire resistance testing (with both masonry and steel door present in the assembly) and referencing studies, rather than relying only on certification of the isolated components.

- Pay special attention to wall thickness, original mortar condition, and interface detailing when planning retrofits in historic buildings.

The fire performance of a historic wall–steel door assembly cannot be assumed from the separate fire resistance of the elements. For accurate risk assessment and reliable compartmentation, both must be considered as a system.